Biocomposite Solutions

Discover the science behind our products and understand how your choice contributes to the global effort towards sustainability.

our product lines

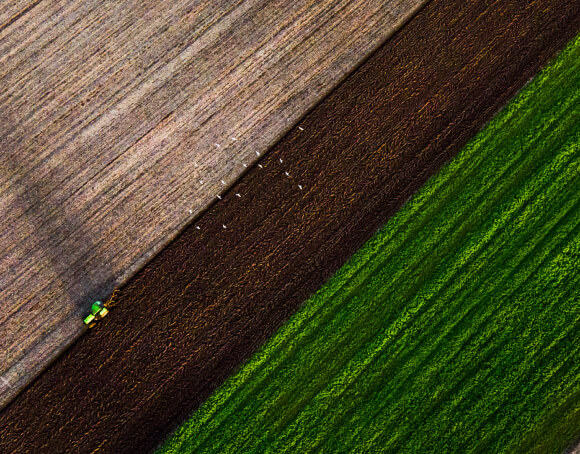

Construction Materials Should be Grown in Fields

Humanity has advanced fundamental science to the point where this statement becomes valid. Now, it's time to focus on applied research, take action, and move toward a sustainable future. We have chosen this path and invite like-minded individuals to collaborate with us.

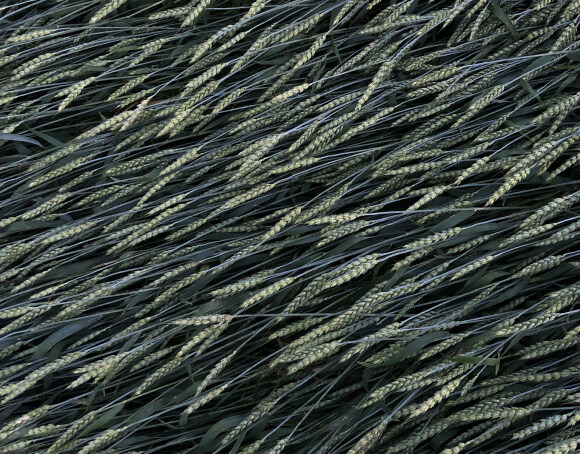

Biocomposites from Crops

Grown in the Fields and Must Be Biodegradable at the End of Life Cycle

Biodegradable at the End of Life Cycle

Grown in the Fields and Must Be Biodegradable at the End of Life Cycle

can be used in architecturec

Biocomposites that Look Like Natural Materials

Biocomposites are increasingly being utilized across various industries. Our biocomposite products stand out due to their remarkable resemblance to natural materials such as wood, stone, and others. These unique materials are specifically designed for architectural applications and are distinguished by their intricate manufacturing process, making them truly exceptional on the market.

Stone

Wood, stone, semi-transparent glass-looking material etc.

Wood

Wood, stone, semi-transparent glass-looking material etc.

Glass

Wood, stone, semi-transparent glass-looking material etc.

applications of our biocomposites

Specifically for the 3D Printing of Parametric Architectural Shapes.

Efficient, reliable, and sustainable biocomposite pellets for modular and large-format 3D printing. We empower manufacturing companies to create advanced products while remaining firmly within the bounds of a circular economy.

bioComposite 3D Printing

Flexibility

Flexibility is freedom in customizing parts’ design and geometries. Directly from 3D CAD design to production, technologies empower manufacturers to transform their ideas into reality.

bioComposite 3D Printing

Efficiency

Optimized manufacturing processes result in shorter lead times and reduced operating costs without compromising on parts’ mechanical and functional properties.

bioComposite 3D Printing

Sustainability

Zero-to-positive environmental impact: drastically cutting waste, using only needed raw and recycled material, limiting the need for storage, supports or tools and making circular economy possible.

applications of our biocomposites

Collaborative with Hillside Contracting: Parametric Stairs Made of our Biocomposites

Hillside Contracting creates state-of-the-art parametric stairs using 3D printing technology and our biocomposite materials. This serves as a proof of concept, validating the quality of our product.

HillsideStairs

Explore Our Biocomposite Solutions for Your Next Construction Project.

Trusted by Industrial Leaders

contact form

Speak with Our

Experts

Experts